That company, Traxys, is projected to help Li-Cycle accomplish $300 million in revenue alone. They have over 40 contracts with various “blue chip” suppliers through 2030, including one company that’s both an investor and a supplier.

The company locates the “spokes” near suppliers they’ve got long-term agreements with. In their press release, the company says, “Li-Cycle’s process does not require high temperatures, no wastewater is produced, and only low level emissions are generated from operations.” Presumably, the unneeded materials, like battery casings and plastic separators, are sent back to other recyclers, reducing the amount of transportation the company needs. Their methods are supposed to come up with 95% of the valuable battery materials, so there’s not a lot of waste involved. They mechanically process the worn out batteries and then send them to the “hubs” for further processing. The “spokes” are decentralized facilities located close to the source of supply (where recyclable batteries come from). Li-Cycle says it uses patented “Spoke & Hub” technologies to do this without burning or heating the batteries. At the end of the process, the more of the good stuff you can sell again to be used in new batteries, the better.

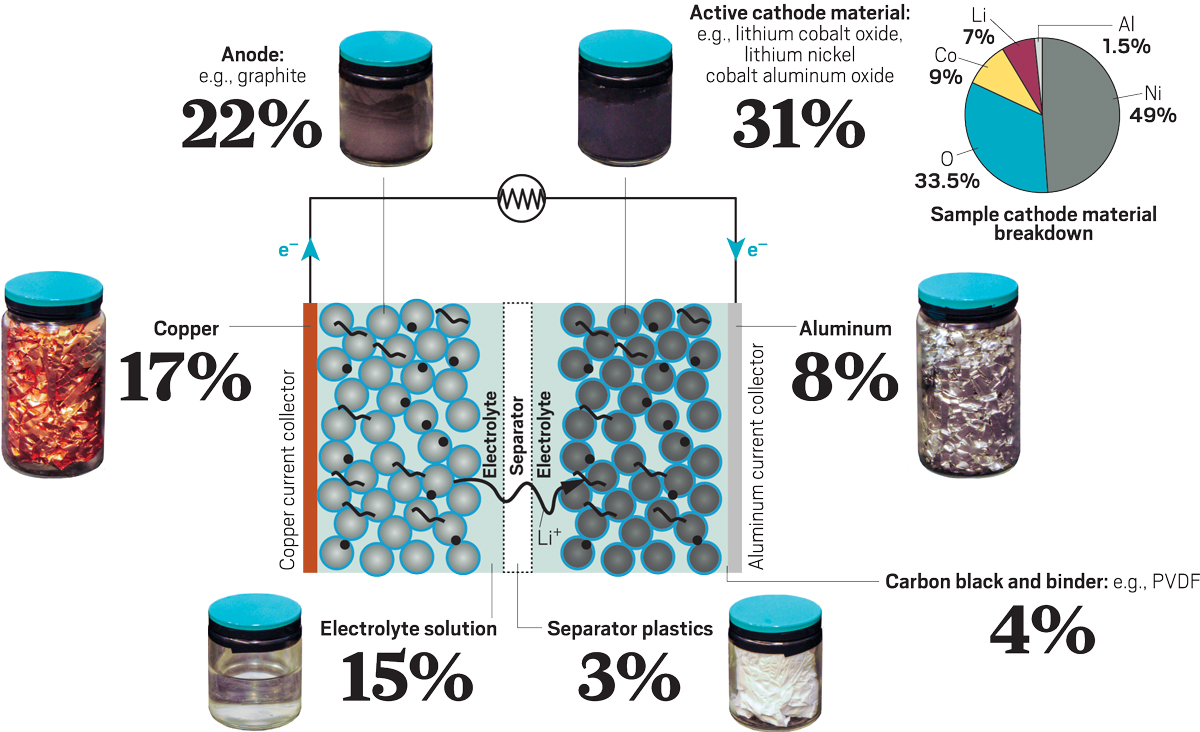

They also end up with less of the useful lithium and other materials in the end, so it wasn’t as profitable. According to the company, such processes are dangerous and release toxic gases, making them less than ideal. Li-Cycle needed to build an infrastructure to get those batteries into its operation, tear them down safely, and recover the materials for return to battery manufacturers.īefore Li-Cycle, most companies used “thermal operations” to release the valuable materials from the batteries they were built into. Given the complex nature of lithium battery cells (cathode, anode, separator, case, and more), this isn’t as easy as it might sound. Li-Cycle was founded in Canada in 2016 with a goal to not only recycle batteries, but to also turn a profit doing it. “The partnership with the Peridot team is an exciting and important milestone in Li-Cycle’s journey, further enabling Li-Cycle to achieve our mission and grow in lockstep with our customers - in North America and globally.” Our ‘future proofed’ technology can recycle any battery chemistry economically, and our closed-loop solution provides the essential raw material building blocks for batteries that are in critical demand,” said Tim Johnston, Co-Founder and Executive Chairman of Li-Cycle.

“We see a tremendous global market opportunity in front of us driven by the exponential growth of the electric vehicle market. Jokes about bugs aside, this is important because it shows us that battery recycling is not only possible, but that it’s happening on an industrial scale. The new company, Li-Cycle Holdings, will be listed on the New York Stock Exchange as LICY. Now North America’s largest lithium-ion battery recycling company is going public through a deal with a special purpose acquisition company (SPAC). So, the thinking goes, let’s just keep rolling coal because that’s somehow better. The more informed shills know that they’re asking a disingenuous question, but many other people buy into the argument that batteries cannot be recycled and that we’re walking into an environmental disaster with EVs. “What are we going to do with all of those batteries?” they ask. One of the biggest issues EV naysayers and fossil fuel shills bring up is the future of each and every EV.

0 kommentar(er)

0 kommentar(er)